- April 13,2023

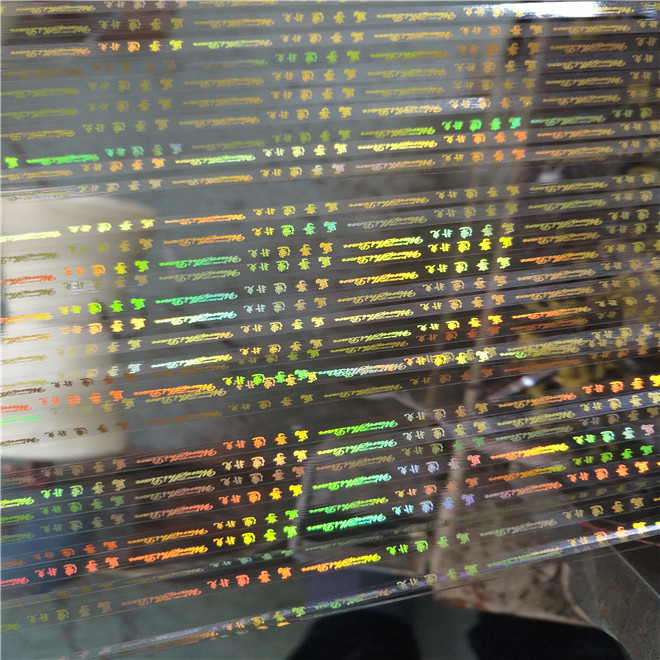

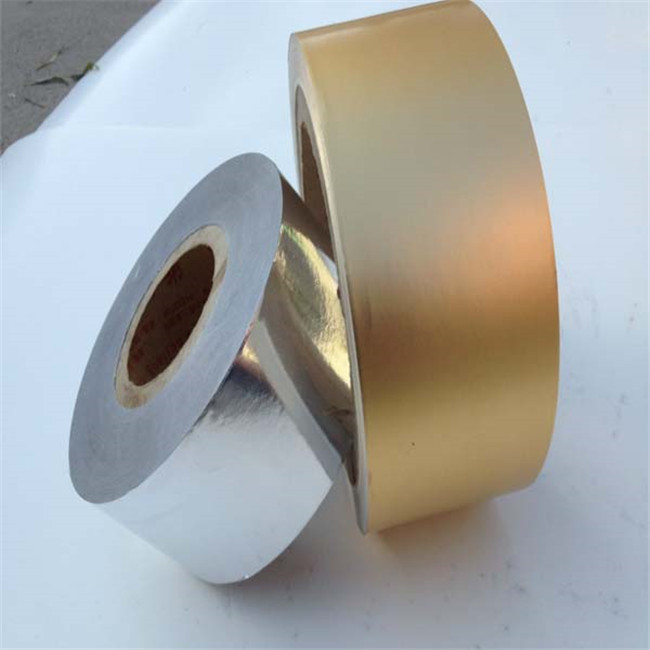

New Trend Hot Stamping Foil Tipping Paper

Compared with the hot stamping technology of the cigarette pack, the tipping paper hot stamping technique is more difficult in some aspects. The tipping paper is attributed to the reel type data, and most of them adopt the round pressing and hot stamping method, and there are all hot stamping and single-plate hot stamping. The hot stamping equipment is mainly made up of domestic equipment, such as Zhejiang Haining Tengda, Ruian Qiang, Xi'an Black Bull equipment, and imported equipment, which is typical of France's Chambon. The heating method is heated by electricity or oil. The bronzing plate cylinder is a full version. It cannot be used as a partial version of the cigarette pack. The base material is copper and steel (the copper has good heat conduction function and the steel has high printing durability).

Because the weight of tipping paper products is low, usually 40g/m2, the temperature and humidity requirements of the workshop are high. It is best to adhere to constant temperature and constant humidity, and the hardness and raw materials of the impression cylinder are also high. request. In the tipping paper hot stamping technology, the factors affecting the quality of the product have the following aspects.

1. The influence of electrochemical aluminum

In the hot stamping process of tipping paper products, the quality of anodized aluminum is related to the quality of hot stamping. If the tightness of the anodized aluminum is not appropriate (too loose and too tight), the hot stamping will not be true; the temperature of the hot melt adhesive will not cause the hot stamping paste; the curing time of the electrochemical aluminum will be too long or too short, and the tension will be too much. Large or too small, the hue is not correct or unstable will directly affect the quality of the goods. Zhejiang Wenzhou Taichang, Wenzhou Yushi, Guangdong Sihui Sun and other companies produce the quality of the aluminum foil for hot stamping. To a certain extent, grasping the quality of the electrochemical aluminum is appropriate to control half of the quality of the goods.

2, the impact of hot materials

The influence of the hot-selling materials on the quality of the hot stamping of the tipping paper products is now on the ink layer of the appearance of the hot materials. If the white ink as a thinner in the ink participates in an excessive amount, the aluminum will be reversed, resulting in false stamping. In addition, the temperature resistance and thickness of the ink layer will also affect the quality of hot stamping products, especially when printing pearlescent inks.

3, the impact of hot stamping speed

The hot stamping speed is too slow, the hot stamping is not clear (except for special requests), following the progress of the speed, the function of the anodized aluminum and the hot stamping temperature, the hot stamping pressure reaches the best condition, the pictures, texts and lines on the merchandise It becomes clear. The speed of the tipping paper is mostly 40 meters per minute, and should be adjusted according to the clutter of the picture, the size of the text, and the thickness of the line.

4, the impact of hot stamping temperature

The unevenness of the hot stamping temperature plays an important role in the quality of the product. The hot stamping temperature is too high, and the drawing is simple, and the temperature is too low, so that the hot stamping is not easy. The use of oil or electric heating methods, the use of copper or steel as a substrate of the bronzing plate is also very different in temperature control, usually equipped with a temperature checker, mainly used to check the actual temperature of the bronzing version.

5, the impact of hot stamping pressure

The hot stamping pressure mainly refers to the pressure of the rubber press roller on the bronzing plate, which also plays a proper main effect in the tipping of the tipping paper. If the pressure is too small, the hot stamping will not be caused. The paste will be caused by the assembly, and the service life of the tipping paper may be shortened. When setting the pressure, it should be gradually added from small to large.

Following the development of hot stamping technology, the cold hot stamping and hot stamping technology that is used on the cigarette pack will also be used on the tipping paper. Regarding the tipping paper production company, it should follow the footsteps of the cigarette pack and position it from the beginning

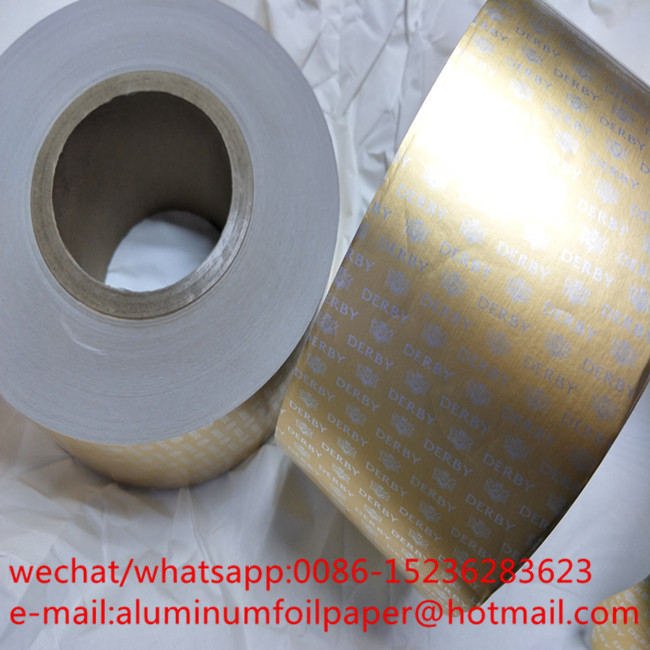

Luoyang Xinyuantong Industry Co., Ltd specialized in cigarette packing material field for 24 years with good quality and competitive price. We can offer a variety of aluminum foil paper products such as embossed aluminum foil paper, aluminum foil laminated paper, gold & silver board paper, tongue paper (inner frame) and other cigarette parking materials like tipping paper, tear tape, BOPP film. Besides,we have ISO9001-2008 certificate.